A simpler, more predictable service model

AEVA has introduced a modular maintenance framework designed to reduce downtime and streamline routine servicing. Instead of relying on specialized technicians, operators can now replace common wear components using a simple mechanical latch system. The update makes AEVA units behave more like durable industrial hardware than experimental robotics platforms.

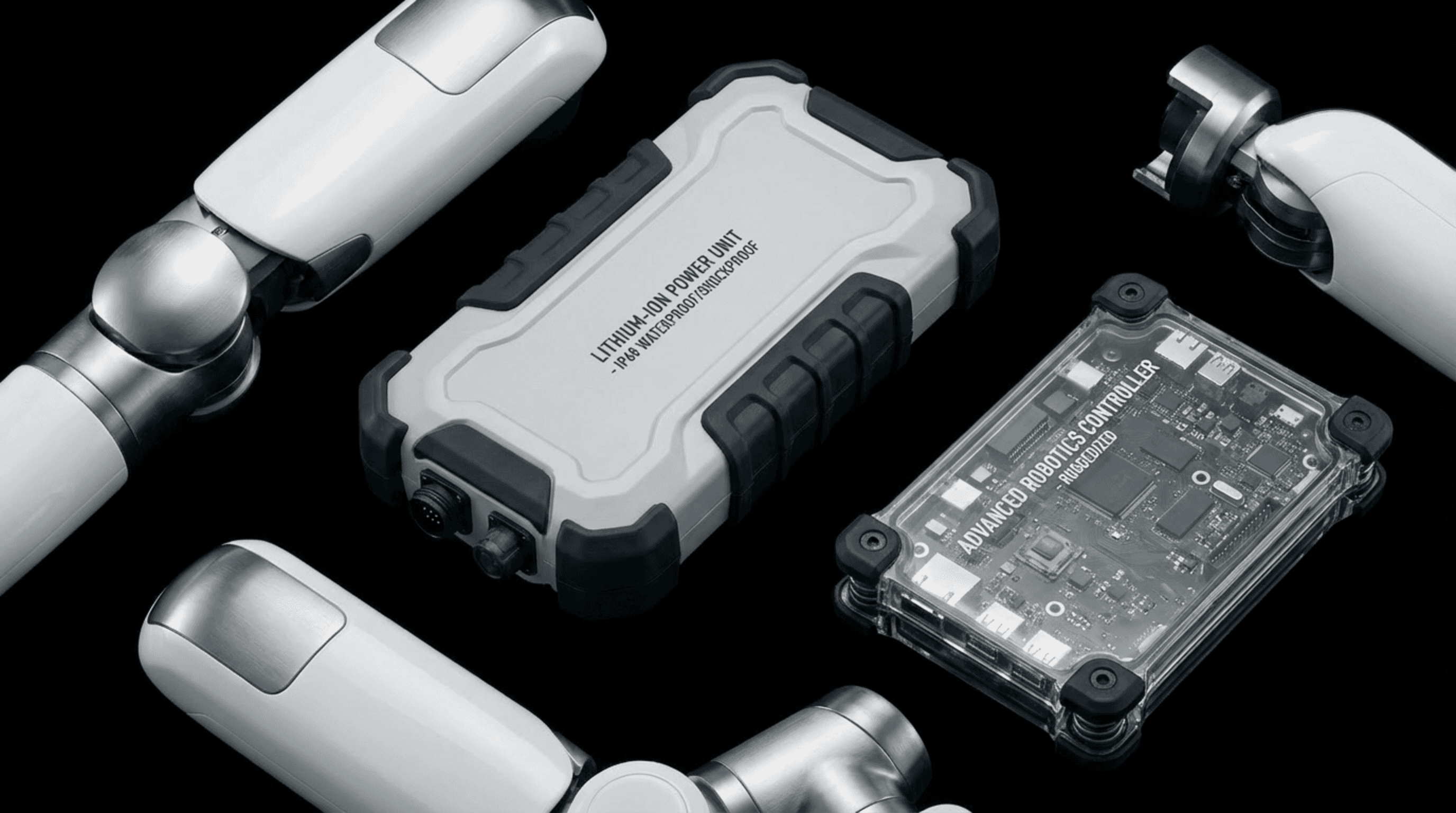

Designed for operators, not engineers

High-use parts such as gait actuators, balance-assist joints and environmental seals are now packaged into sealed modules that slide out cleanly. AEVA’s goal was to eliminate the typical multi-step diagnostic process and make routine maintenance as straightforward as changing a consumer-grade device shell. Internal calibration remains automatic, so no fine adjustment is required after replacement.

Bench data shows consistent time savings

Early testing at AEVA’s Bay Area calibration lab indicates an average 43 percent reduction in service time across commercial deployments. Pilot operators in hospitality, office logistics and private home environments reported faster recovery from wear-related issues and more predictable scheduling windows.

Component-based maintenance system cuts service time by 43 percent

Rolling out to all current units

The modular system is being introduced across all AEVA-UNIT 079-E7 models, with retrofit kits planned for existing field units. As AEVA scales manufacturing and expands global deployments, the simplified maintenance model is expected to support higher uptime and lower operator workload.