A facility built for precision at scale

AEVA Systems has officially opened its new manufacturing site in the Bay Area, marking the company’s largest infrastructure investment to date. The facility is designed around a simple principle: autonomous systems only scale reliably when their mechanical and calibration standards scale with them. The new site brings together component machining, assembly, stress testing and end-of-line calibration under one roof.

Engineering-forward layout and controlled environment

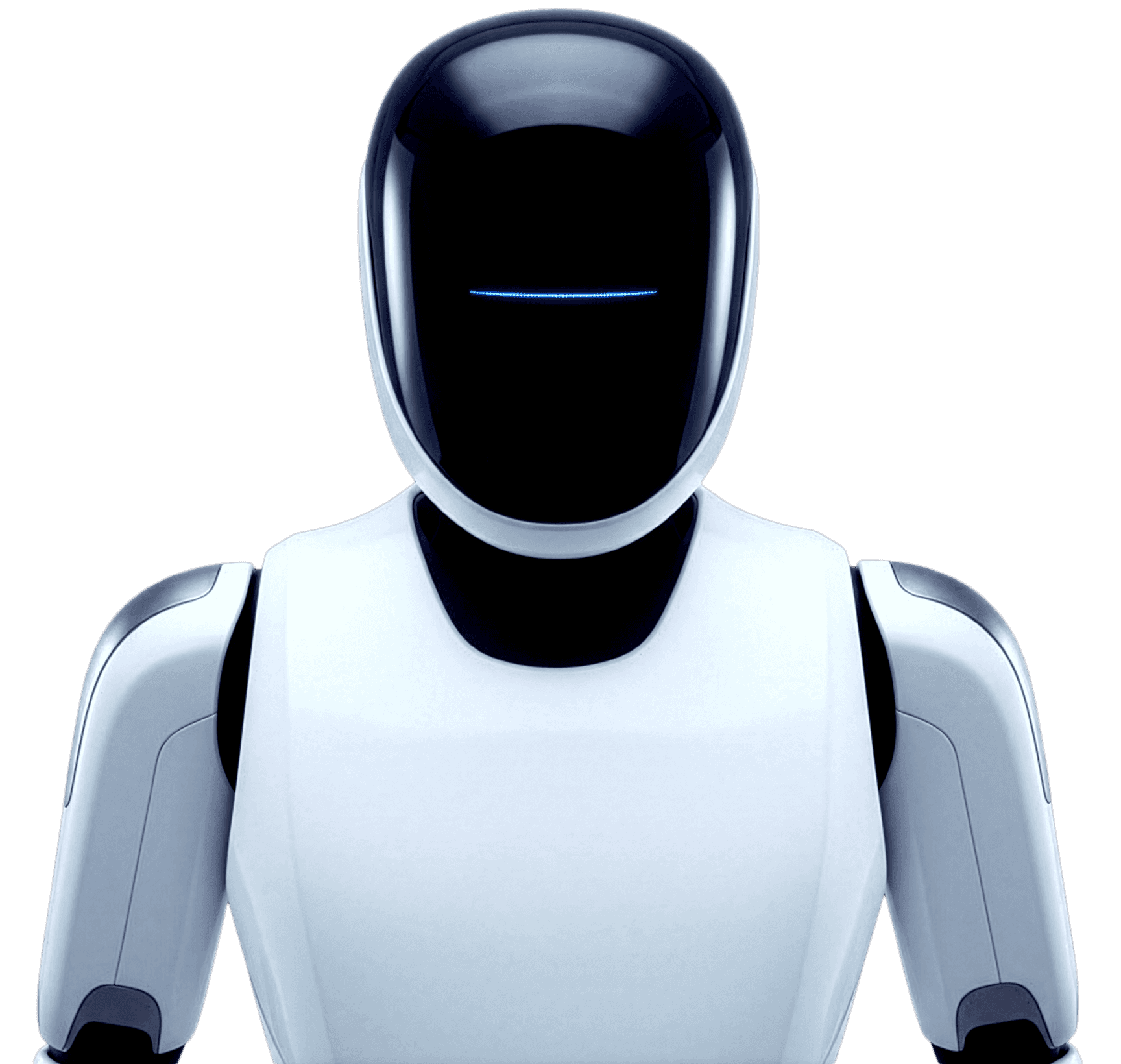

The building is structured as an ultra-clean, high-tolerance production environment. AEVA’s sealed gait actuators, low-noise motor assemblies and environment-mapping sensors now move through dedicated manufacturing lanes with tightly monitored tolerances. Several areas of the facility operate under controlled temperature and vibration thresholds to ensure repeatability in every unit produced.

The factory is not optimized for speed, but for consistency. Each AEVA-UNIT 079-E7 undergoes methodical verification procedures before leaving the production floor.

Strengthening local talent and global deployment

The Bay Area location provides immediate access to machining specialists, robotics engineers and safety researchers, many of whom collaborate directly with AEVA’s R&D nodes in Tallinn and Singapore. The new facility also shortens the time between prototype iteration and production-grade verification, allowing engineering teams to validate mechanical improvements in real-world conditions more efficiently.

A landmark step toward controlled scale

AEVA emphasizes that the gigafactory does not signal mass deployment. Instead, it supports a long-term goal: a manufacturing pipeline where every autonomous unit behaves like predictable hardware, not a variable software experiment. The new Bay Area site will form the backbone of AEVA’s manufacturing capacity for the coming years, enabling higher volume without compromising the company’s deterministic engineering philosophy.